Thinking of buying a Used Scissor Lift? Read on for answers to common questions about scissor lifts and to find prices on units available near you.

What Is a Scissor Lift?

Scissor lifts are a type of mobile elevated work platform that is commonly used for jobs inside buildings such as ceiling work, putting signs up, and maintenance tasks.

With a lower working height than boom lifts, scissor lifts typically only reaching 20 to 50 feet in height.

When Should I Use a Scissor Lift?

Scissor lifts are used in manufacturing and industrial jobs because they have large platforms that can accommodate both persons and materials.

Lifts provide a secure and dependable deck for employees to perform tasks that require them to operate at heights.

The scissor lift’s power lies in its ability to extend while working and then fold into a size that’s easy to be readily stowed, a feature that makes it a viable competitor to a common ladder.

Scissor lifts come with either an electric or a diesel engine.

Electric engines are suitable for interior use since they do not require ventilation like gas engines do. As indoor work is typically less demanding, battery life is not typically an issue.

A scissor lift is an excellent tool for keeping personnel working very high safe, regardless of the project or height.

How do I Move a Scissor Lift to My Jobsite?

Scissor lifts are typically moved to a job by a step deck or flatbed truck.

Operators use forklifts or ramps to get the scissor lift on or off the truck.

What do People Use Scissor Lifts for?

- Indoor maintenance in areas with higher ceilings.

- Scissor Lifts can be used in Schools, Warehouses, Hospitals, etc.

- Warehouse work and general upkeep, including reaching high shelves in a safe manner.

- Sign maintenance, which necessitates a wider platform for safe operations.

- Working on sloping or uneven ground

- Working in small outdoor settings that necessitate up-and-down lifting movement

Common Uses for Scissor Lifts

Some jobs seem custom made for scissor lifts. Scissor lifts are perfect for inside tasks since they are easy to use, especially if the project simply requires moving up and down repeatedly. Scissor lifts can be used outside on rough or sloping ground. A rough terrain scissor lift was designed specifically to work on rugged or uneven terrain, allowing people and materials to work at heights in ways that a normal ladder could not.

Used Scissor Lifts

When maintained, used scissor lifts can be a great value for someone looking to get a job done for less. While manufacturers can sometimes offer special financing deals if you have perfect credit, getting a new scissor lift can take longer than buying used.

Scissor Lift Prices

Comprehensive Scissor Lift Pricing Guide: Scissor Lift prices vary based on height, features, and specifications. A 19′ lift typically ranges from $10,000 to $15,000. For lifts between 20-30′, expect to pay up to $50,000.

Scissor Lifts with heights between 35′ and 60′ can cost between $20,000 and $75,000.

Keep in mind, additional factors such as platform capacity, power source, and brand will also impact the final price. To ensure the best value, compare multiple options and consider renting or purchasing used equipment if it meets your needs

Scissor Lift Rental

If you have a short-term need for a scissor lift, renting can be useful. Click here to see a list of scissor lift rental stores across the United States.

How much does it cost to rent a scissor lift? Rental rates vary widely by location and duration of rental job. For example, a 19-foot electric scissor lift has an average rental rate between $100 and $150 per day, between $350 and $500 per week, and between $900 and $1,200 per month. These prices vary by region.

How Do I Choose the Right Scissor Lift for My Job?

The type and height of scissor lift that will work best for a job will be determined by the project’s requirements. Knowing the nature of the job site at the time the scissor lift will be utilized will help you decide “which scissor lift is best.”

Electric scissors are ideal for inside jobs, while Diesel-powered scissor lifts will provide the machine with the necessary power to maneuver about the job site –especially in rough-terrain environments.

You should know how high up that you’ll need to reach to complete your job. Are you working indoors on a flat surface? – A slab scissor lift would be a smart choice.

If you are working outside, on uneven terrain, or on unfinished ground, a rough terrain scissor lift is best.

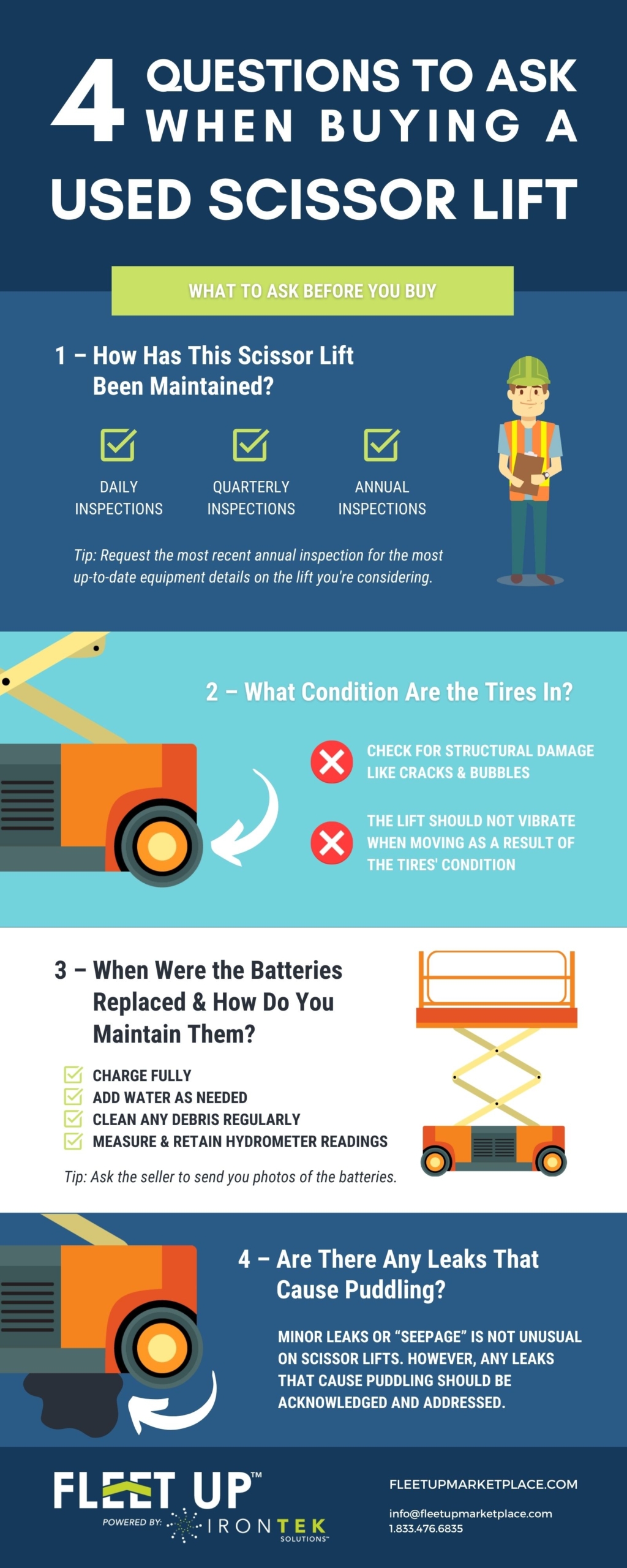

Infographic: Buying a Used Scissor Lift

Make sure to ask the seller the following 4 questions to help ensure that you’re getting a good lift that has been properly maintained:

Safety First! Safety Concerns for Scissor Lifts

There is risk with using any type of construction machinery, including scissor lifts. The new ANSI A92.24 standard requires scissor lift operators, their supervisors and non-operator occupants to be trained to help avoid falls, injuries on the platform and electric shocks / electrocution.

To help keep you safe on a scissor lift, here are several things to keep in mind:

- Do not use a scissor lift until you have been properly trained.

- Know where the scissor lift’s emergency stop and lowering button is and how to use it

- Do not operate equipment like a scissor lift by yourself

- Wear a safety harness and required Personal Protective Equipment

- Keep tools secured when you are on a scissor lift

- Check out where you will be working before getting into your lift, both the ground and the space above and below your working height.

- Do not move a scissor lift that is fully extended, and do not move it remotely or from the ground if anyone is on it