Push-Pull Forklift: Enhancing Efficiency

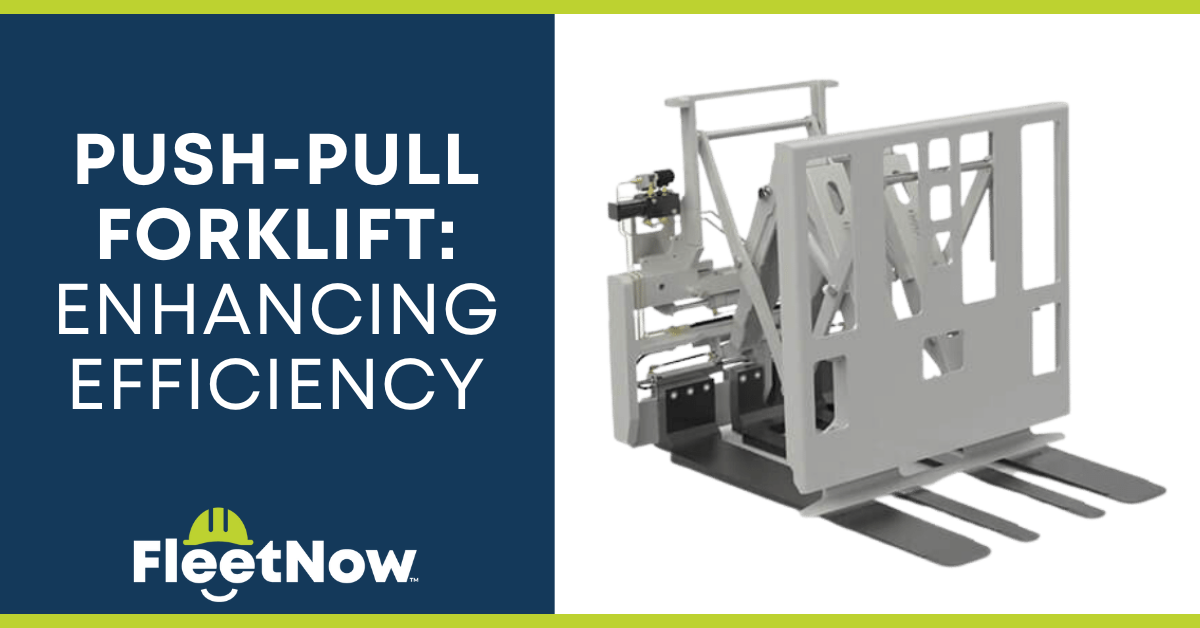

A push-pull forklift, also known as a push-pull attachment or push-pull attachment for a forklift, is a specialized piece of equipment used in material handling and logistics applications. It is typically attached to the front of a forklift and is used to handle various types of loads that are difficult to manage with just the standard forks of a forklift. The primary function of a push-pull attachment is to handle loads without pallets or slip-sheeted loads.

How A Push-Pull Forklift Works

Push-pull forklifts work by using a specialized attachment mounted to the front of a forklift to handle loads that are difficult to manage with standard forks. These attachments typically consist of hydraulic arms or clamps that can be extended and retracted to engage with the load.

Types of Push-Pull Forklifts

Push-pull forklifts are not typically categorized by types in the same way that forklift attachments are. Instead, push-pull forklifts refer to forklifts equipped with push-pull attachments, which are specialized attachments used for handling loads without pallets or with slip sheets. The primary variations in push-pull forklifts involve the types of push-pull attachments and their features. Here are some common variations:

Push-Only Attachments: These attachments are designed specifically for pushing loads, making them suitable for applications where loads need to be pushed onto racks or into tight spaces. They are not equipped for pulling loads.

Pull-Only Attachments: Pull-only attachments are specialized for pulling loads. They are often used in situations where materials need to be extracted from racks or containers.

Combined Push-Pull Attachments: Some push-pull attachments are versatile and can both push and pull loads. These attachments offer greater flexibility for handling various materials and load-handling tasks.

Applications & Industries

Push-pull forklifts with their specialized attachments find applications in a variety of industries and material handling scenarios. Their versatility in handling loads without pallets or with slip sheets makes them valuable in different contexts. Here are some of the common industries where push-pull forklifts are used:

- Warehousing & Distribution Centers

- Manufacturing

- Food & Beverage Industry

- Automotive Industry

- Pharmaceuticals & Healthcare

- Retail & E-Commerce

Considerations Before Buying

Before incorporating push-pull forklifts into material handling operations, operators must be trained and certified. Compatibility between the push-pull attachment and the specific forklift model is essential to avoid operational issues. Careful assessment of load weight and size, as well as load stability, ensures that the attachment can handle the intended materials safely. Proper installation of the attachment is critical to prevent accidents and equipment damage. Regular maintenance and inspections are also vital to ensure the attachment remains in good working condition. Addressing these considerations not only enhances safety but also maximizes the benefits of push-pull forklifts in various material handling scenarios.

Check Out This Video That Gives An Overview of the Push-Pull Forklift Attachment:

Where Can I Find Push-Pull Forklifts For Sale?

Forklift extensions can be found through online marketplaces, like FleetNow, heavy equipment dealers, like ACE Attachments, or local dealers, which can often be found through manufacturer’s websites. A well-known manufacturer of forklift attachments is Blue Diamond Attachments.

Learn more about Blue Diamond Attachments in our blog post titled “Blue Diamond Attachments: Reviews, Models & Where to Buy.”

Frequently Asked Questions (FAQs)

What is a push-pull forklift and how does it differ from a standard forklift?

A push-pull forklift allows you to ship, receive, and warehouse unit loads on inexpensive slip sheets rather than pallets. Utilizing a push-pull forklift can be a more cost-effective solution for many businesses. The key difference lies in the way push-pull forklifts handle loads. While standard forklifts use forks to engage with pallets, push-pull attachments use a combination of hydraulic clamps and a push-pull mechanism. This allows them to grasp and push or pull slip-sheeted loads, which are typically flat sheets of material, such as cardboard or plastic, that replace traditional pallets. Push-pull attachments are particularly useful when handling various load types or when switching between palletized and slip-sheeted loads frequently.

Are push-pull attachment compatible with all forklift models?

No, push-pull attachments are not necessarily compatible with all forklift models. Compatibility depends on various factors, including the design and specifications of both the forklift and the push-pull attachment.

How can companies ensure the safe operations of push-pull forklifts?

Companies can take several measures to promote safe operation including making sure operators are certified, conducting routine equipment inspections, and ensuring attachments are compatible with the specific forklift.